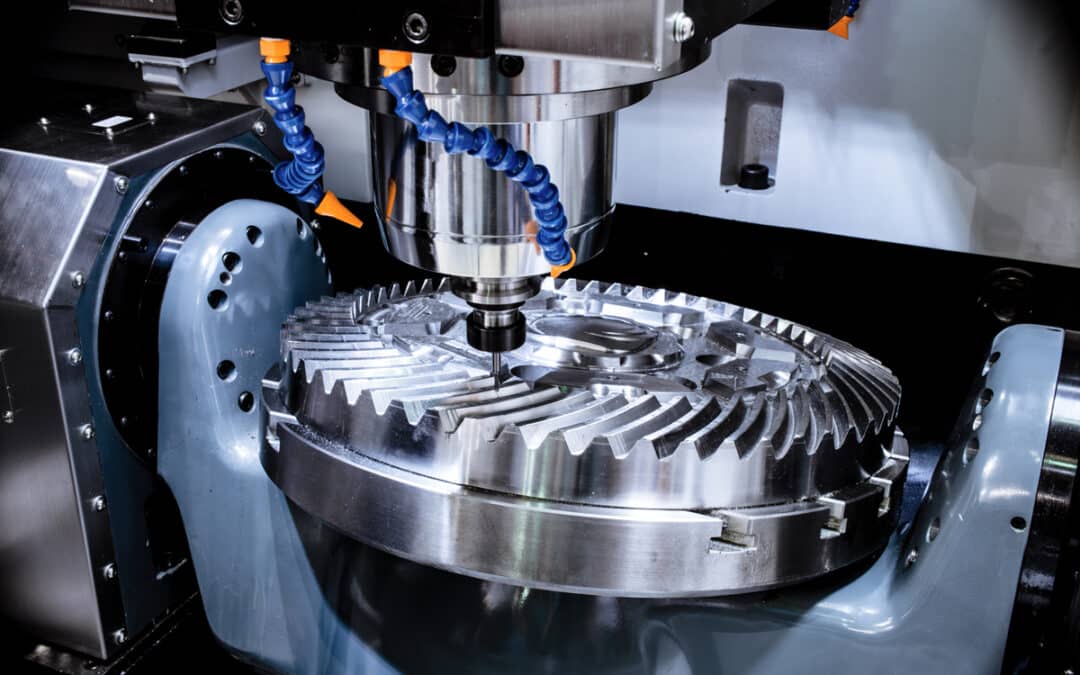

Engineering and procurement teams face production delays and quality drift when their CNC precision parts move through fragmented supplier networks. Each handoff introduces variation, slows qualification, and increases the likelihood of mismatched tolerances that affect downstream assembly. These issues become more visible in aerospace, defense, and high-reliability commercial manufacturing, where stable processes and verifiable repeatability are mandatory.

A consolidated approach to CNC precision machining eliminates these variables. By working with a single-source machining partner like MME, teams gain a controlled workflow where machining, secondary processing, inspection, and quality documentation are handled in-house to support tight tolerance profiles, complex geometries, and demanding material requirements.

Table of Contents

What Problems Arise When CNC Precision Parts Manufacturing Is Split Across Multiple Vendors

Process Variation

When projects depend on multiple vendors, the qualification workload expands, and process variation increases. Each supplier interprets prints, tolerances, tool strategies, and inspection methods differently, which produces inconsistent incoming inspections and measurement disagreements. This creates additional risk when precision machining is required for aerospace and defense systems.

Schedule Integrity

Split production also affects schedule integrity. Gaps between manufacturing steps, inconsistent communication, and uncontrolled change management disrupt production timelines, forcing engineering teams to troubleshoot avoidable issues.

Fragmented Workflows

Fragmented workflows further increase administrative overhead. Supplier drift, incomplete traceability, and mismatched documentation introduce complications that slow down procurement and increase total program costs.

How a Single Source Manufacturing Partner Improves Speed, Control, and Quality

Unified Manufacturing Source for Consistent Results

When precision machining, secondary processing, inspection, and documentation are all performed in-house, engineers gain a stable environment where manufacturing steps adhere to the same standards and interpretation of the print. This eliminates variation introduced when multiple shops apply different tooling philosophies, setup methods, or measurement techniques.

Shared Fixturing and Centralized Programming Improve Repeatability

Consistent fixturing and centralized programming strengthen part repeatability across entire part families. Instead of rediscovering manufacturing strategies from supplier to supplier, one integrated team maintains all process knowledge. This supports continuity from machining through secondary processing and finishing while keeping dimensional behavior predictable across builds.

In-House Metrology Stabilizes Process Capability

In-house metrology closes the loop by bringing inspection, machining feedback, and corrective actions into the same workflow. Engineers receive fast, accurate visibility into process capability, allowing adjustments to be made early, before variation compounds. This is critical for tight tolerance and long-run aerospace and defense programs.

Key Gains From a Consolidated Workflow

- Reduced handling and lower risk of part damage

- Improved dimensional stability across repeated builds

- Fewer non-conformances and less engineering rework

- More reliable lead time performance

- Clearer communication between engineering and manufacturing teams

What Engineering and Procurement Teams Gain by Consolidating With MME

MME brings complex geometries, tight tolerance profiles, and advanced materials into one controlled machining environment. This provides continuity from machining through secondary processing, finishing, and inspection without the disruptions that come with managing multiple vendors. By keeping programming, tooling strategy, and documentation unified, machining intent stays consistent, and part variation stays in check across every build.

Procurement and Engineering teams benefit from:

- Fewer vendors to manage

- Strong traceability across all manufacturing stages

- Faster, cleaner change management

- Long-term supply stability backed by controlled processes

Simplify Production With MME

When teams consolidate their CNC precision parts production, they gain greater control, higher quality, and faster throughput across the entire manufacturing lifecycle. Eliminating handoffs between vendors reduces variation and removes delays that slow critical manufacturing programs.

MME provides a complete in-house manufacturing environment for CNC precision parts, supported by engineering, secondary processes, inspection, and quality systems built for demanding industries.

Learn more about MME’s in-house capabilities today!