In industries like aerospace, defense, and commercial manufacturing, even the smallest failure in sealing can have massive consequences. A tiny leak can ground aircraft, compromise mission-critical electronics, or even result in safety violations that halt production entirely.

When precision and performance are non-negotiable, Form-In-Place (FIP) gaskets offer a powerful solution. These highly customizable seals are engineered for demanding environments, and at MME, we don’t just apply them; we integrate them seamlessly into our CNC-machined components for unmatched quality and control.

This article will walk you through the what, why, and how of FIP gasketing and how MME ensures reliability from design to delivery.

What is an FIP Gasket?

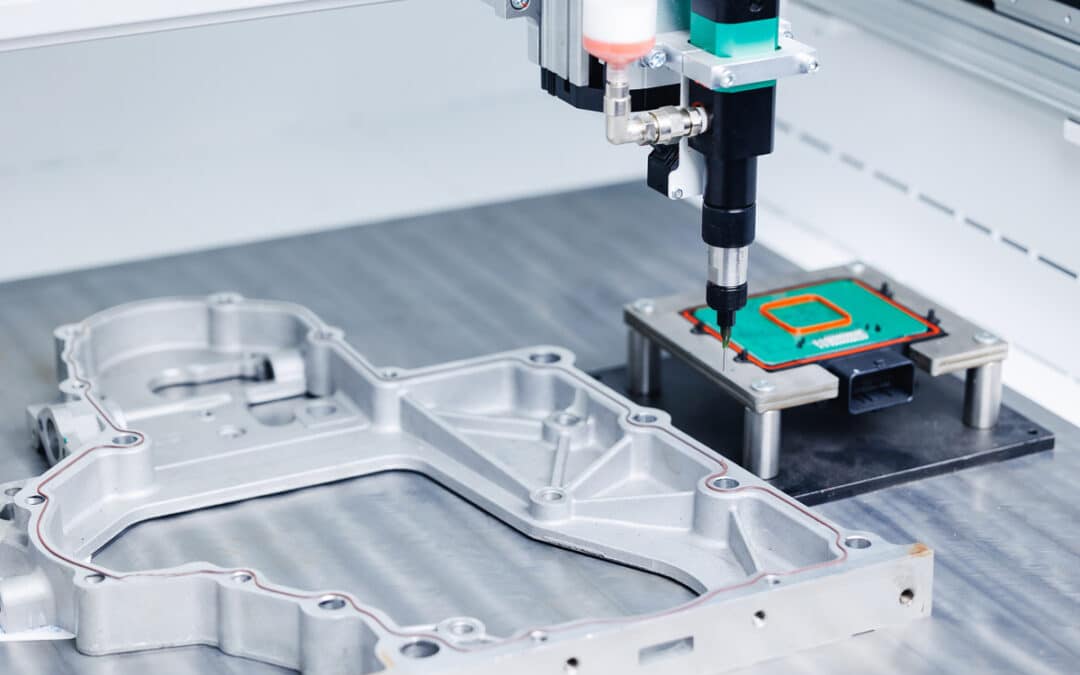

A Form-In-Place gasket is a precision-dispensed elastomer bead applied directly onto a part’s surface, forming a seamless seal that conforms to tight tolerances and unique geometries. But at MME, we don’t treat the gasket as an afterthought—we treat it as a core part of your component’s performance strategy.

What may be a basic seal elsewhere becomes a mission-critical feature in our shop, engineered, applied, and inspected to spec with total production accountability. We apply each FIP gasket in-house to ensure perfect alignment with the component’s geometry, material, and mechanical requirements. This eliminates fit-up issues, reduces handoffs, and gives us full control over every parameter: from bead profile and cure time to torque retention and thermal cycling.

How Do FIP Gaskets Withstand the Demands of High-Performance Environments?

High-performance environments demand high-performance sealing. FIP gaskets rise to the challenge by providing:

- Thermal resistance to extreme temperatures and altitude conditions

- Durability against vibration and pressure fluctuations

- Material compatibility with aerospace alloys and rugged composites

- Protection for mission-critical electronics used in military and aerospace applications

- Compliance with quality systems such as AS9100 and MIL-STD requirements

These attributes make FIP gaskets indispensable in applications where failure is not an option.

What Engineering and Operational Advantages Do FIP Gaskets Offer?

FIP technology offers a unique combination of flexibility and control:

- No tooling required, making it ideal for rapid prototyping and short-run production.

- Customizable bead profiles for complex geometries and varied surface finishes.

- Reduced assembly time, thanks to single-step, integrated sealing.

- Lower material waste compared to die-cut alternatives.

- Precision robotic dispensing ensures consistency, repeatability, and tight tolerances.

- Inline quality control catches issues before they reach the customer.

Why Pair CNC Machining with In-House Gasketing?

Precision sealing is only as reliable as the process behind it. When FIP gasketing is outsourced, you introduce unnecessary handoffs, risk dimensional mismatches, and slow down iteration cycles. MME eliminates these challenges by performing both CNC machining and gasket application in-house, within one integrated workflow.

Here’s how in-house gasketing sets MME apart:

1. Design-to-Dispense Continuity

Our CNC team and gasketing engineers work from the same CAD model, sharing tooling strategies, fixturing insights, and functional tolerances. This cross-disciplinary collaboration ensures the gasket bead path is not only accurate but optimized for the actual machined surface with no assumptions, no translation errors, and no back-and-forth with outside vendors.

2. Dimensional Integrity and Bead Control

FIP gaskets are highly sensitive to surface preparation, groove depth, and part flatness. By machining and dispensing in the same facility, we maintain continuous control over these variables. The result is exceptional bead profile consistency, repeatable compression performance, and fewer downstream QA rejections.

3. Faster Iterations and Change Management

When design changes are needed due to tolerance stack-ups, enclosure redesigns, or material shifts, our in-house teams can pivot quickly. There’s no waiting for new tooling or third-party response times. We can reprogram the bead path and adapt dispensing parameters in hours, not days.

4. Fewer Hand-Offs = Reduced Risk

Every external handoff introduces potential failure points: shipping damage, handling errors, and miscommunication between vendors. At MME, your parts stay in a controlled environment from the first setup to final inspection, dramatically reducing scrap rates and field failure risks.

5. Scalability Without Compromise

From one-off prototypes to full-rate production, our in-house robotic dispensing systems are calibrated for scale. We use the same precision platforms and quality protocols across volumes, so you get consistency at every phase, without tooling lead times or capex constraints.

Partner with MME for FIP Gasket Sealing

In industries where failure isn’t an option, your sealing method matters. FIP gaskets deliver unmatched precision, repeatability, and compliance, and when paired with in-house machining, they reduce risk and accelerate production.

At MME, we’re not just applying gaskets. We’re building performance into every part we machine. Learn more about our FIP gasket capabilities today!