Unlock the potential of your product design with custom manufacturing and engineering. Enhance efficiency and accelerate time-to-market by partnering with industry leaders who prioritize quality, innovation, and seamless product design and manufacturing transitions.

In aerospace, defense, and commercial industries, the essence of a successful product often lies in its design. In these spaces, custom manufacturing and engineering not only ensures superior results but also guarantees a seamless transition from concept to production. Overall, every detail in product design and manufacturing contributes significantly to a product’s success in these markets. However, as design complexities and requirements increase, so do the challenges.

The question then becomes, how can engineers enhance the quality of their product design while managing cost and time efficiency? In addition, how can they do so while optimizing customer satisfaction? The answer is adaptability, versatility, and connecting with a manufacturing partner that places quality first.

What Makes Product Design Quality Important?

For engineers in high-stakes industries, product designs must align with stringent quality standards. Subsequently, product design quality directly impacts functionality, customer satisfaction, and brand reputation. High-quality product design ensures that the product meets user expectations and regulatory standards while remaining cost-effective and efficient in production. Furthermore, a well-designed product can significantly reduce production errors, lower costs, and improve the time-to-market, thereby enhancing the overall competitiveness of a business.

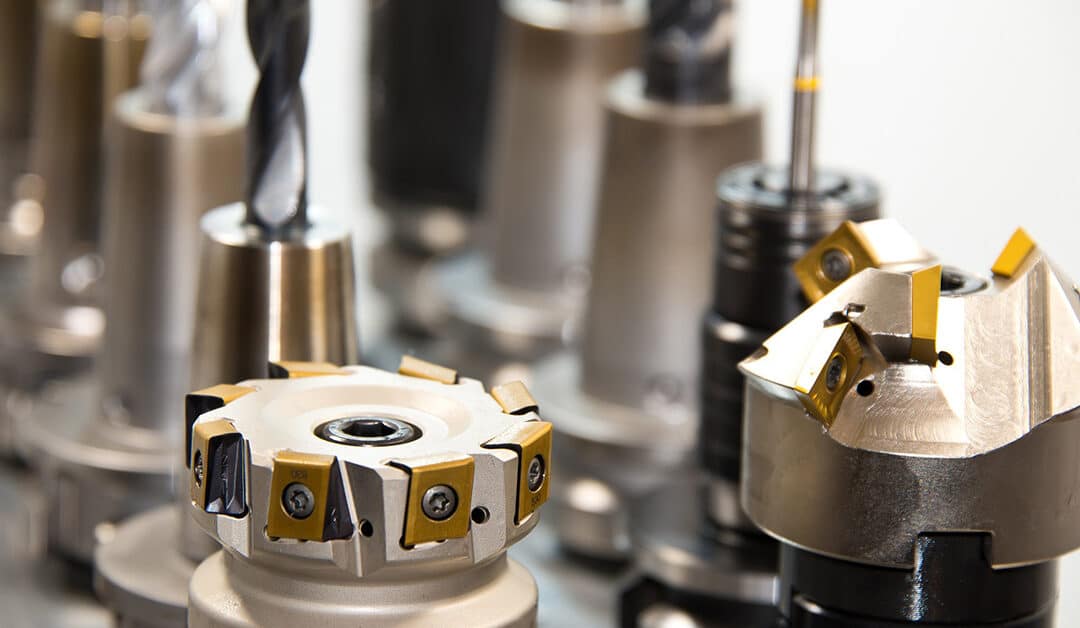

Custom manufacturing and engineering play pivotal roles in this regard. By leveraging cutting-edge design techniques and integrating them with advanced manufacturing processes, companies can create products that excel in performance, durability, and user satisfaction. Essentially, the quality of product design determines the ease with which a product can transition from a blueprint to a tangible, market-ready item.

How to Improve Product Design

1. Understand the User Experience

The foundation of any successful product design is a deep understanding of the user experience. By employing user-centered design principles, businesses can create products that are intuitive and satisfying for users. This approach involves engaging with end-users during the design phase to gather insights about their needs and preferences, which can then be integrated into the design.

2. Incorporate Continuous Feedback

One of the most effective ways to enhance product design is through continuous feedback. This involves iterative testing and refinement based on real-world use cases. By establishing feedback loops with stakeholders, including engineers and end-users, businesses can identify areas of improvement early in the development process. This proactive approach reduces costly revisions later on and results in a more refined product.

3. Leverage Advanced Technologies

Utilizing the latest tech in design and manufacturing can significantly enhance product outcomes. Tools such as computer-aided design (CAD) software enable precise modeling and simulation, allowing for the anticipation and rectification of potential design flaws before production begins. Integration of technologies like 3D printing for prototyping can also accelerate the design process and improve the accuracy of the final product.

4. Focus on Material Selection

Material selection is the foundation of product design and manufacturing. The choice of materials impacts not only the aesthetic and functional quality of the product but also its manufacturability and cost. Collaborating with material scientists and engineers during the design phase can provide valuable insights into the most appropriate materials for a given application, optimizing performance and durability.

5. Partner with a Contract Manufacturer like MME

Partnering with a contract manufacturer such as Modern Manufacturing & Engineering, Inc. (MME) can provide access to a wealth of resources, expertise, and advanced technologies that enhance product design and manufacturing. MME holds NADCAP certifications and offers a range of services, including precision CNC manufacturing, expert engineering, and secondary processes like assembly and painting.

A partnership like this guarantees improved quality, shortened production time, and refined designs. In addition, provides engineers the confidence that they have a reliable partner during every stage of the production lifecycle.

Quality Begins with Collaboration

In summary, improving product design involves a multi-faceted approach that includes refining design processes, integrating innovative technologies, and collaborating with experienced partners like Modern Manufacturing & Engineering, Inc. With MME, engineers are not only gaining access to state-of-the-art manufacturing capabilities but also benefiting from expert knowledge and innovative solutions that drive forward-thinking design strategies. The team emphasizes that the foundation of superior product design is built on collaboration, ensuring that each one is approached with a holistic perspective that values input and innovation at every stage – from conceptualization to final production.

Explore how MME can contribute to your next project and discuss your specific design requirements. Contact the team today for your custom quote.