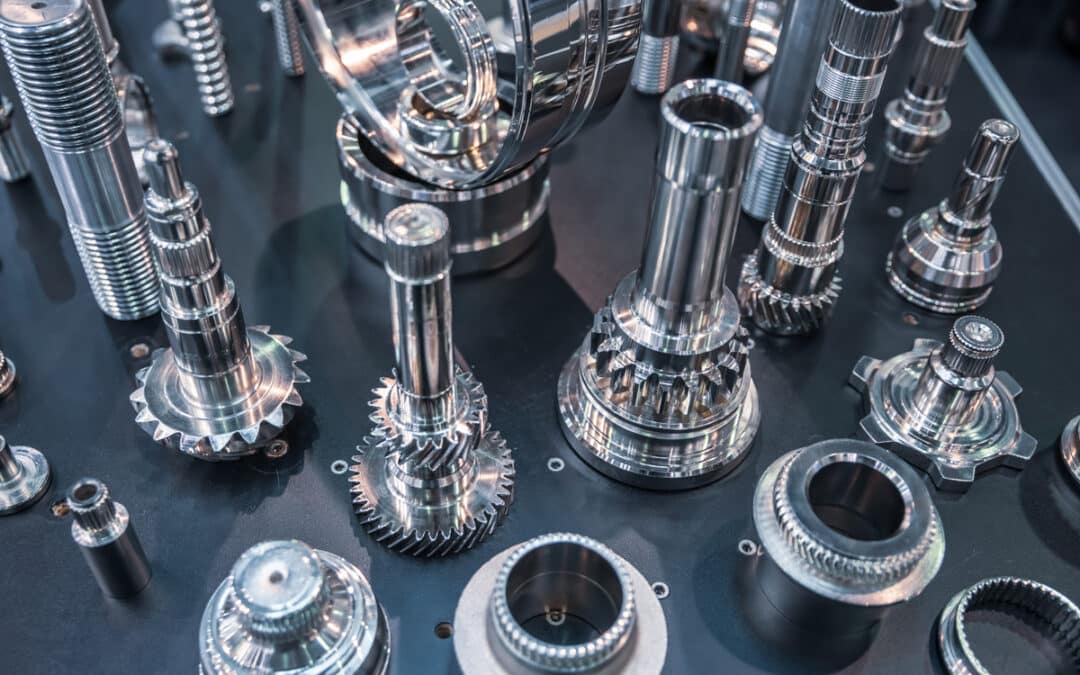

When aerospace parts move from design into production, issues can emerge even when designs are technically sound. Engineers and procurement teams often see cost overruns, schedule delays, quality concerns, and redesign cycles that were not apparent in CAD or simulation. In many cases, these issues stem from a misalignment between design intent and real-world CNC machining realities.

This is where CNC precision engineering becomes critical. By applying manufacturing-focused engineering earlier in the process, teams can design parts that maintain performance requirements while moving more efficiently into production. MME’s component engineering services give aerospace teams a practical path to bridge design and manufacturing, reducing downstream risk and supporting smoother transitions from design to production.

Why Do Aerospace Designs Struggle to Move Cleanly Into Production?

Aerospace industry professionals already understand the regulatory, performance, and reliability requirements tied to flight-critical components. The challenge is not a lack of technical knowledge. The challenge is that complexity compounds quickly when manufacturability is not addressed early enough.

Tolerance stacking, complex geometries, material behavior, and inspection constraints all interact once a part enters CNC production. If CNC process capability is not considered during design, small decisions can drive larger issues such as excessive setups, extended cycle times, inspection bottlenecks, or inconsistent results.

These issues are not inevitable. When CNC precision engineering is applied early, teams can proactively address manufacturability risks instead of reacting to them later in production.

Common Aerospace Part Design Mistakes and How CNC Precision Engineering Services Avoid Them

Even experienced aerospace teams encounter recurring design challenges that only surface during CNC production. Without early manufacturing alignment, these issues escalate quickly, impacting cost, lead time, and quality across aerospace programs:

1. Overconstraining Tolerances Without Process Context

Common challenge:

Tolerances are specified tighter than functional requirements, which compounds tolerance stack up, reduces yield, and increases inspection burden across complex aerospace components.

Solution:

CNC precision engineering aligns tolerance requirements with proven CNC process capability, improving repeatability and cost control without compromising performance.

2. Designing Complex Geometries Without Considering CNC Accessibility

Common challenge:

Feature placement that appears efficient in CAD can require excessive setups or specialized tooling once CNC machining begins, increasing cycle time and variation risk.

Solution:

CNC precision engineering services evaluate geometry through machining strategy, tool access, and fixturing realities to support efficient, repeatable production.

3. Specifying Surface Finishes Without Functional Differentiation

Common challenge:

Surface finishes are specified during design, but without a clear functional justification. This can drive tighter process controls, additional operations, and higher cost without improving part performance.

Solution:

CNC precision engineering services support design teams by evaluating surface finish requirements in the context of machining capability and part function, helping ensure specifications align with aerospace requirements and production efficiency.

4. Ignoring Inspection and Quality Control Requirements During Design

Common challenge:

Parts may meet dimensional intent yet remain difficult to inspect consistently due to limited access or measurement constraints, increasing compliance risk.

Solution:

CNC precision engineering supports designs that are both machinable and verifiable within aerospace quality systems.

5. Deferring Manufacturing Input Until After Design Finalization

Common challenge:

When manufacturing input is delayed, design issues surface after processes are already defined, making changes costly and disruptive.

Solution:

Early involvement and input from manufacturing teams reduce redesign cycles and accelerate production readiness by identifying manufacturability risks earlier.

How Can Engineers Leverage MME’s Capabilities?

By engaging MME’s CNC precision engineering services early, engineers can evaluate part designs against manufacturing realities before production begins. This allows teams to refine geometry, tolerance profiles, and design intent with a clearer understanding of how parts will be machined and inspected.

This early engagement supports more predictable production outcomes by aligning manufacturing-focused design decisions from the outset, reducing revisions and improving confidence in quality and repeatability as parts move into machining.

Partner With MME

Avoiding common aerospace part design mistakes requires intentional engineering involvement before production begins. Partnering with MME’s engineering services early allows teams to evaluate design decisions against real manufacturing and inspection conditions while still retaining flexibility to refine the design.

This early collaboration is a critical step in reducing downstream risk. CNC precision engineering services help ensure tolerance strategies, geometries, and quality requirements are aligned with manufacturing processes, supporting predictable production outcomes and long-term program stability. Ready to get started? Explore MME’s engineering capabilities online today!