Modern product design continues to push the limits of manufacturability. As assemblies shrink, tolerances tighten, and environmental requirements grow more demanding, traditional gasketing methods can introduce unacceptable variability. For engineers balancing precision and production efficiency, those limitations create real design and reliability risks.

At MME, precision manufacturing drives every solution. Our automated form-in-place gasket dispensing systems have become essential for engineers who need consistent sealing performance across complex geometries and high-stress environments. This article examines where conventional gasket methods fall short and how MME’s form-in-place gasket dispensing process addresses today’s most persistent engineering and production challenges.

Why Traditional Gaskets Fall Short

In advanced manufacturing, traditional gasketing techniques often create more problems than they solve.

- Manual variation: Hand-applied or die-cut gaskets introduce inconsistency, leading to uneven compression, leaks, and rework.

- Tooling constraints: Every design update requires new dies or molds, slowing iteration and increasing cost.

- Space inefficiency: Flat or molded gaskets cannot adapt to compact 3D geometries or narrow sealing paths.

- Assembly complexity: Manual placement and adhesive bonding add time and increase alignment risk, reducing overall repeatability.

- Environmental vulnerability: Exposure to heat, vibration, and chemicals can degrade conventional materials, reducing long-term reliability.

These limitations highlight why engineers are turning to form-in-place gasket dispensing to achieve better control, precision, and scalability in modern designs.

Solving Design Challenges with FIPG Gasket Capabilities

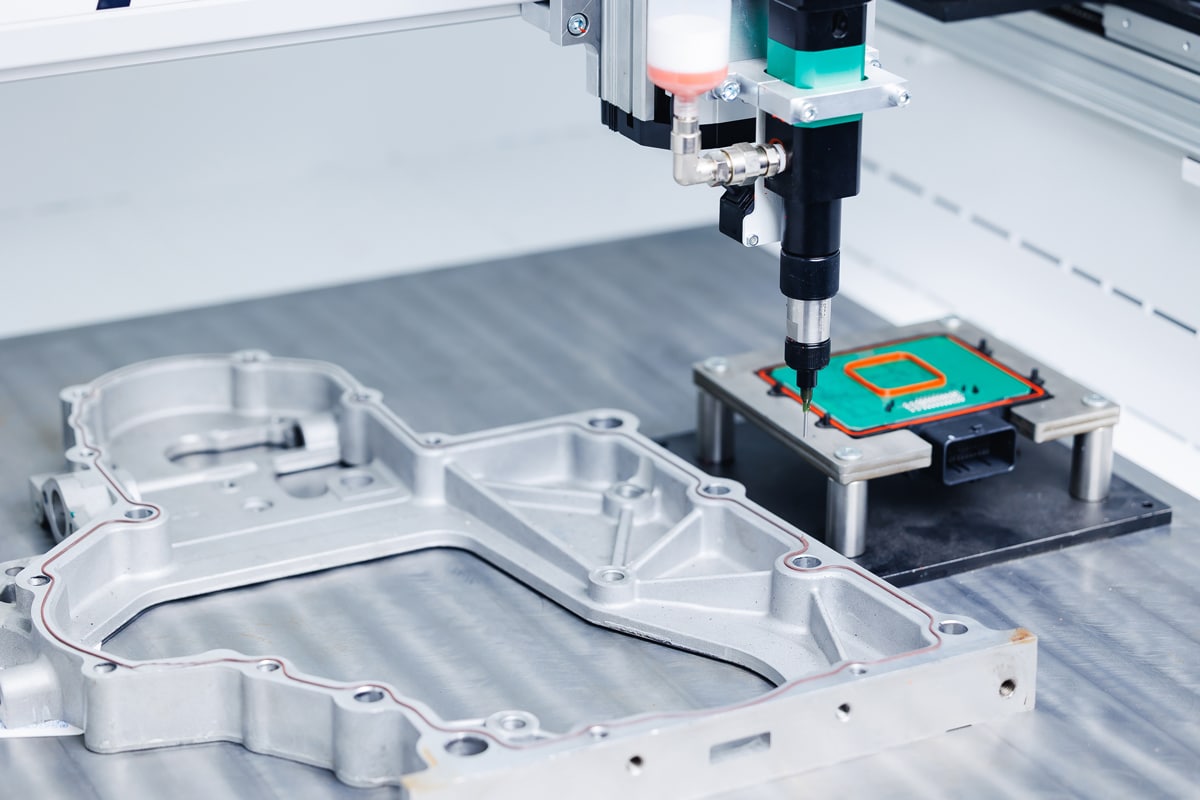

MME’s automated dispensing systems allow engineers to address the toughest sealing and design challenges directly at the source. The technology combines precision dispensing with adaptable materials to deliver accuracy and repeatability that traditional methods cannot match.

Precision Control and Tolerance CompensationForm-in-place gasket

dispensing creates uniform bead dimensions, maintaining consistent compression and eliminating leaks caused by tolerance stack-ups.

Complex Geometries and 3D Surface Sealing

Computer-guided dispensing paths follow curved, contoured, and recessed surfaces, ensuring reliable sealing on designs that exceed the limits of die-cut gaskets.

Miniaturization and Lightweighting

Fine dispensing capability supports smaller components and lightweight assemblies without compromising performance or reliability.

Repeatability and Process Validation

CNC programming ensures identical results in every production cycle. Integrated vision systems and statistical process control (SPC) verify accuracy and consistency.

Material and Environmental Versatility

Form-in-place dispensing accommodates a wide range of materials and can be tailored for specific requirements such as thermal cycling, fluid exposure, vibration resistance, and long-term compression set stability.

Integrated EMI and Environmental Sealing

By dispensing conductive gasket materials, MME combines EMI shielding and environmental protection in a single, efficient process, reducing assembly steps while improving performance.

Design Agility and Faster Iteration

Engineers can adjust gasket geometry by simply updating CAD data: no tooling, no delays, and no material waste.

Design Solutions That Scale from Prototype to Production

Solving design challenges is only part of the equation. The solution must also scale. With form-in-place gasket dispensing, validated bead paths transition directly from development to production without redesign or retooling. Once a process is proven, it can be reproduced with the same precision across every part and batch.

This consistency accelerates product launches, reduces variables, and maintains seal integrity from the prototype through full-scale manufacturing. MME’s controlled process ensures each run performs to the same standard, verified through rigorous testing. Our scalable approach supports demanding applications across aerospace, defense, and industrial markets, where reliability and repeatability are non-negotiable.

Transform Complex Sealing Challenges into Scalable Solutions with MME

MME’s form-in-place gasket dispensing process does more than improve sealing; it enables engineers to meet increasingly complex design requirements with confidence. By combining precision dispensing, material expertise, and rigorous process control, MME helps manufacturers overcome limitations that traditional gasketing cannot. Explore MME’s form-in-place gasket capabilities today!